DT FAQ: How are 3D CAD, 3D Printing related to Digital Engineering?

DE FAQ: How are 3D CAD, 3D Printing & Digital Engineering related?

FAQ Variant(s): How does 3D CAD relate to Digital Twins?; How does 3D Printing relate to Digital Twins?

3D CAD (3D Computer Aided Design), 3D CAE (Computer Aided Engineering) and 3D CAM (Computer Aided Manufacturing) technologies are used to specify precise 3D models or mechanical, electrical, and electro-mechanical products for manufacturing. 3D Printing (a.k.a., Additive Manufacturing) technologies are capable of taking 3D CAD specifications and automatically construcing ("printing") them directly, with neither human intervention nor a separate traditional human-intensive manufacturing process (a.k.a., Subtractive Manufacturing).

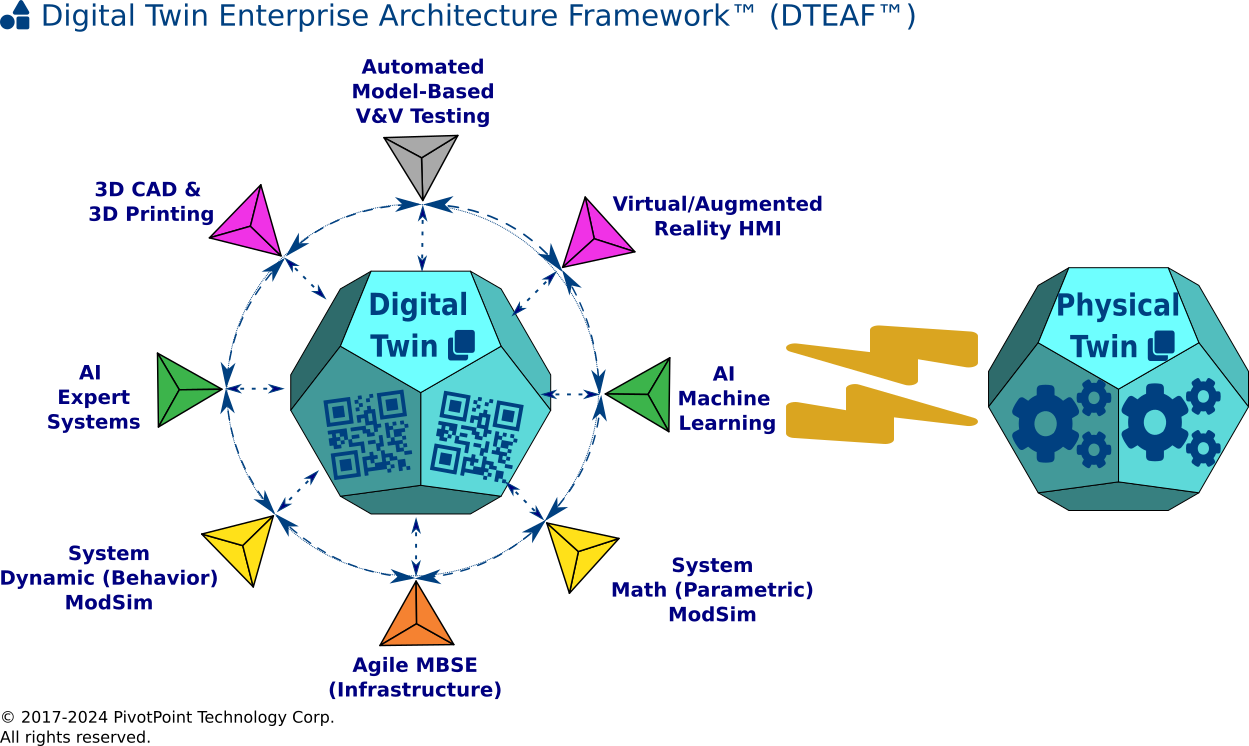

So how do 3D CAD and 3D Printing relate to architecting and designing Digital Twins?

3D CAD & 3D Printing technologies provide the electro-mechanical infrastructure for the physical construction of Physical Twins, and by extension their Digital Twin counterparts. Since the [3D CAD] Design = Implementation [3D Printed Product] principle is rapidly transforming how we design and manufacture Systems-of-Systems, these complementary technologies will play a vital role in the evolution of Digital Twin technology.

DIGITAL TWIN WORKS, DIGITAL TWIN ENTERPRISE ARCHITECTURE FRAMEWORK, DTEAF, AGILE MODEL-BASED SYSTEMS ENGINEERING, AGILE MBSE, and AGILE MBSE 6D EAF are trademarks of PivotPoint Technology Corporation. All other product and service names mentioned are the trademarks of their respective companies.